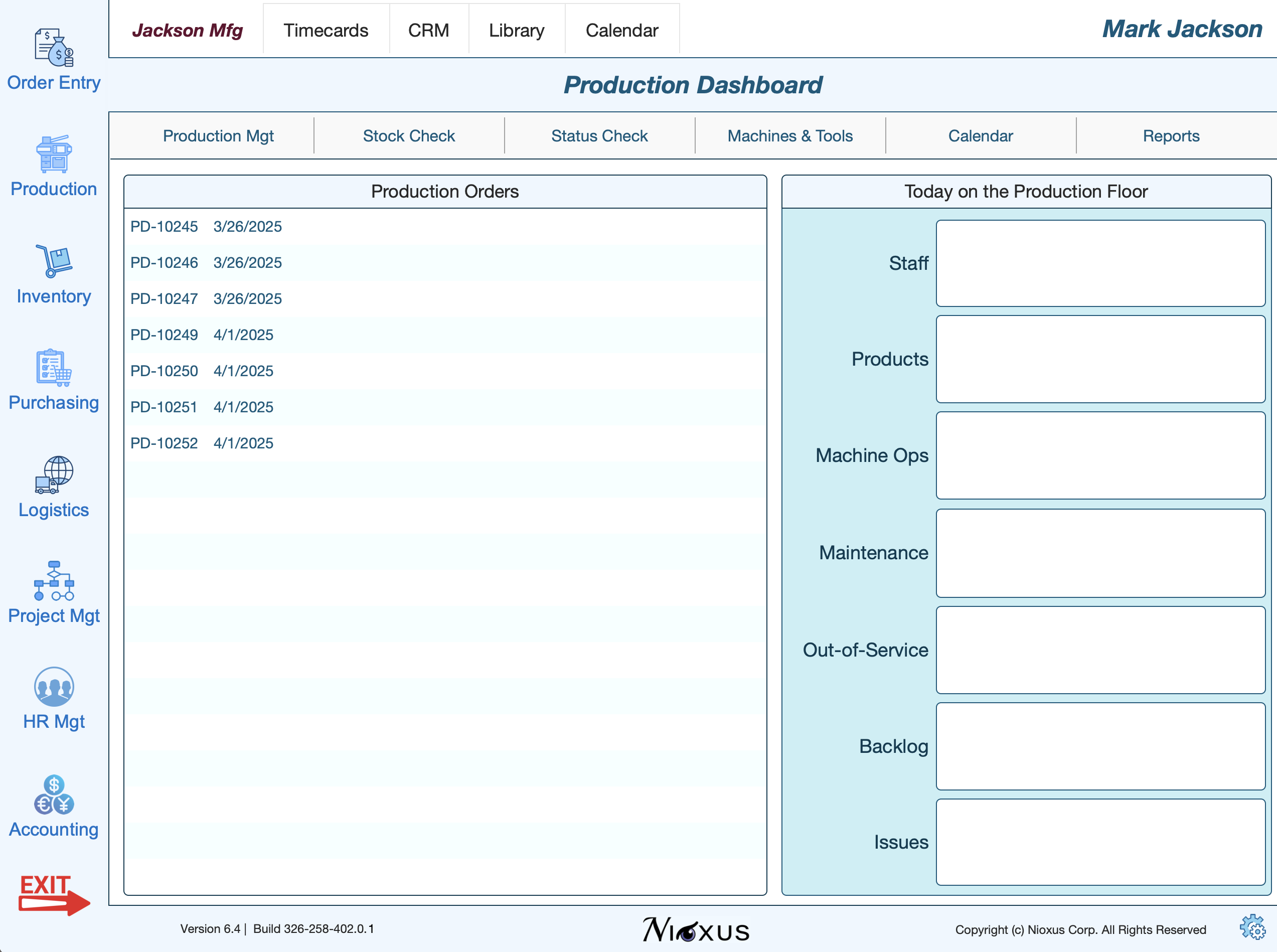

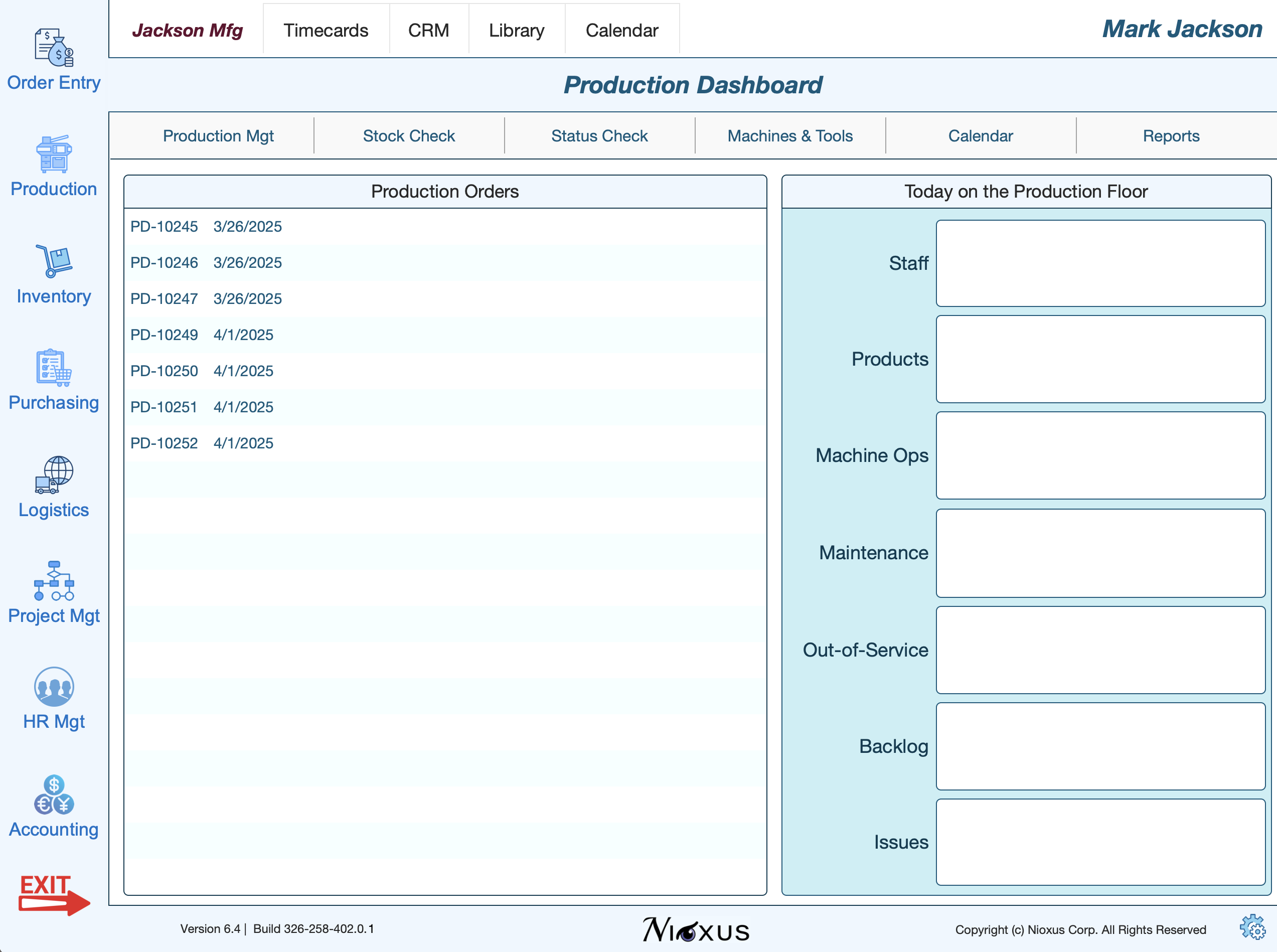

Production Dashboard

Copyright (c) Nioxus Corporation 2025. All Rights Reserved.

Manufacturing &

Job Cost

The Enterprise Manufacturing and Production module keeps the entire shop floor under control and at peak efficiency. Scheduling and load balancing, routine maintenance and prioritized order fulfillment details all drive the optimal production schedule.

Production Orders, Work Orders, Quality Assurance Orders and Inventory Transfers, and every other important link in the production chain is automatically tracked and put in front of the Shop Manager and all the shop floor personnel, so everyone is always on the same page.

To learn more, consult the learning guides and videos below.

Production/Mfg Preview

Production Dashboard

Copyright (c) Nioxus Corporation 2025. All Rights Reserved.

Manufacturing Training Guides

PRODUCTION & JOB ORDERS

Production orders represent the commencement of the production lifecycle. Once approved and scheduled, Production Orders can be used to create an unlimited number of shop floor work orders across all phases of the production lifecycle from fabrication to quality control and stocking.

Production Orders can be created out of sales order lines items when order fulfillment will be via production. Otherwise, Production Orders can be created to restock inventory or satisfy other internal business demands.

Work Orders are the specific instructions and BOMs that will drive shop floor activity within the production lifecycle. Everything from machines and toolings to material requirements and production instructions are part of the work order ensuring that the machine operator knows exactly what s/he needs, when it's needed and how it is to be engaged during production.

Quality Assurance (Completion) Orders are associated with shop floor work orders and are created as finished product comes off the production line. Each work order may result in multiple completion orders and pallets and each completion order can be tracked according to actual materials used, operator and machine line.

Once the production process is complete, finished goods can be grouped by production lot and palleted for transfer into stock inventory, or they can be delivered directly to the order fulfillment and/or shipping department where they will immediately be allocated.

THE SHOP FLOOR

Production Orders can be scheduled according to load balancing metrics, fulfillment requirements or equipment availability. Once scheduled, Production Orders serve as the primary management tool that production managers and executives can use to keep track of progress on the shop floor.

When machines are down due to failure or scheduled maintenance, production schedules can be updated with the appropriate details, which will result in trickle-down adjustments to all remaining production phases and milestones.

In preparation for the next production run, machines, tools and toolings can be prepped and delivered to the shop floor so that everything is where it needs to be to support on-time production and delivery.

Check Out Orders for tools and toolings can be created out of a work order or pre-determined as part of the BOM on the Production Order.

Time cards for human and machine resources are captured according to employee, shift, production run and machine. Job Cost ledgers and product cost sheets are updated in real tiime to reflect the true cost of all non-inventory resource allocations.

Copyright (c) Nioxus Corporation 2025. All Rights Reserved.