Logistics Dashboard

Copyright (c) Nioxus Corporation 2025. All Rights Reserved.

Logistics &

Dock Mgt

The Enterprise Logistics module keeps track of every detail from racking and stacking to picking and packing. Starting with a Pick Ticket and all the way through to the outbound shipment, authorized users will always have real-time access to accurate information regarding every order.

Inbound Receivers, Dock Stock and Inventory Transfers can be bar coded, scanned and moved through the warehousing process using a variety of mobile technologies

To learn more, consult the training guides and videos below.

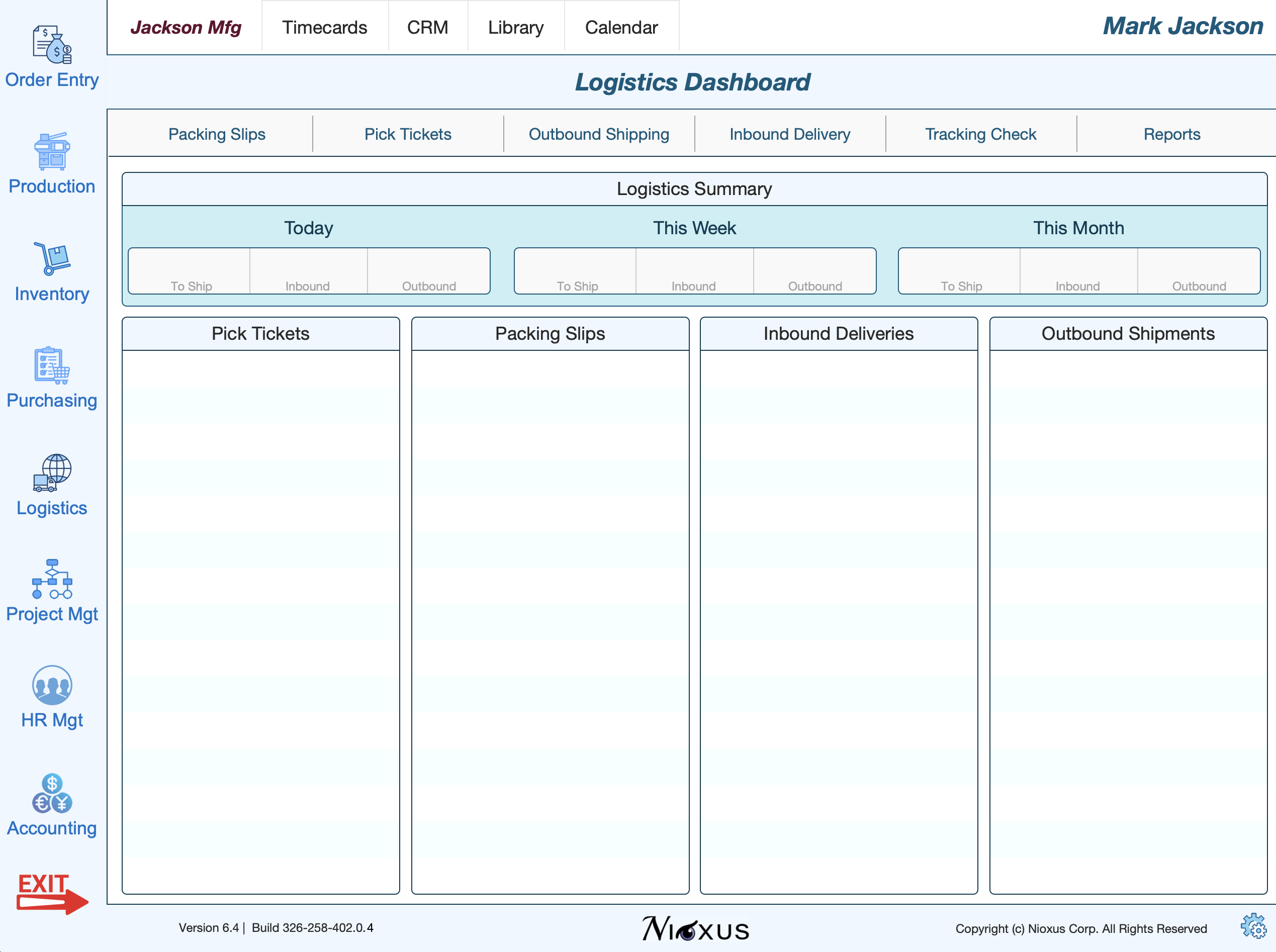

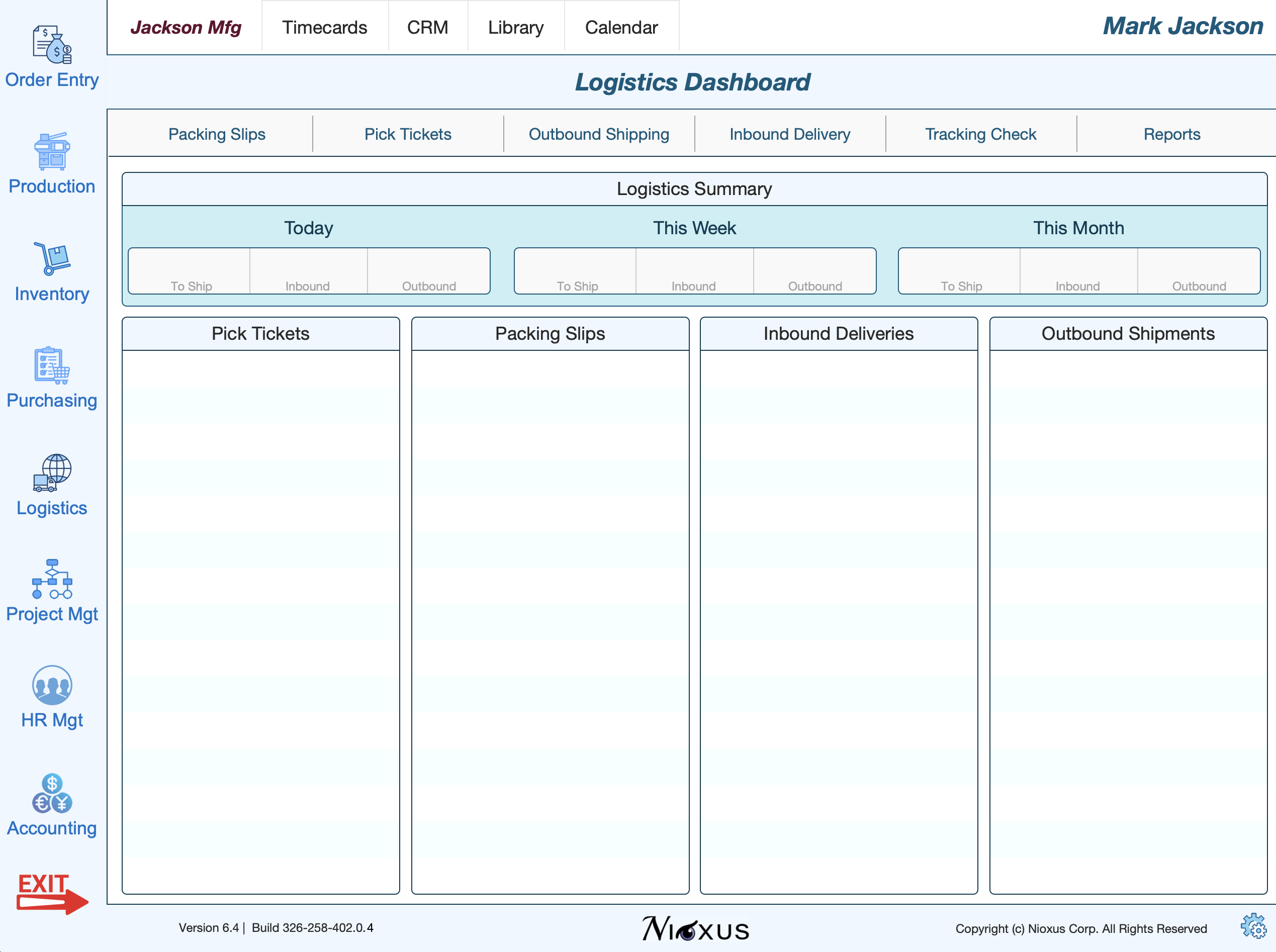

Logistics Preview

Logistics Dashboard

Copyright (c) Nioxus Corporation 2025. All Rights Reserved.

Logistics Training Guides

PICKING & PACKING

When stock needs to be pulled from inventory, whether it's for order fulfillment or to supply the production line, pick tickets define all picking requirements and source locations. Pick Tickets may be linked to sales order line items or production orders so that once inventory is picked, there is a complete audit trail documenting exactly where the items went and why.

Packing Orders serve as the precursor to the packing slip and shipping notice and document exactly what goes into each parcel and how many parcels there are per shipment. When appropriate, sales order and RMA replacement orders are updated when an order gets to the packiing / pre-shipping phase.

Once a shipment leaves the dock, it can be tracked according to sales order number, tracking number or packing order number. Appropriate sales, inventory and logistics personnel can instantly find the status of a package when that information is necessary.

INBOUND RECEIVING

Inbound receiving is organized and efficient in The Enterprise. Whether or not an inbound parcel is linked to a sales order (for fulfillment) or is the result of an approved purchase order, receiver orders document everything from the contents of the shipment to the name of the shipper and the type of vehicle used to transport the goods.

Once received, items will remain at the receiving dock until allocated to sales or production or moved into stock or reserve inventory. Since dock serves as a storage location in the warehousing schema, it is easy to see what's sitting at the dock, why it's there, how long it's been there and where it needs to go next.

When it's necessary to move inventory from one location to another, whether it's in the same warehouse or to a location in a different state or country, the process is easy and straight forward. Inventory transfers can be used to stock service vehicles or other inventories based on any variety of demand metrics. Individual item stock levels are instantly updated when a transfer transaction is entered into The Enterprise.

Stock inventory may be put on hold or held in reserve for a specific customer quote, sales order or manufacturing production order. Held and reserved inventory is not included in available stock numbers, but is included in all inventory costing calculations so that balance sheet reporting is always complete and accurate.

Copyright (c) Nioxus Corporation 2025. All Rights Reserved.